PIAP stated it expects systems like TITAN to be deployed before completion of this years.|Source: PIAP SpacePIAP Space Sp.

z o.

o., a Polish designer of robotics for area applications, aims to use robotics to reduce the time and cost of preserving multimillion-dollar satellites.

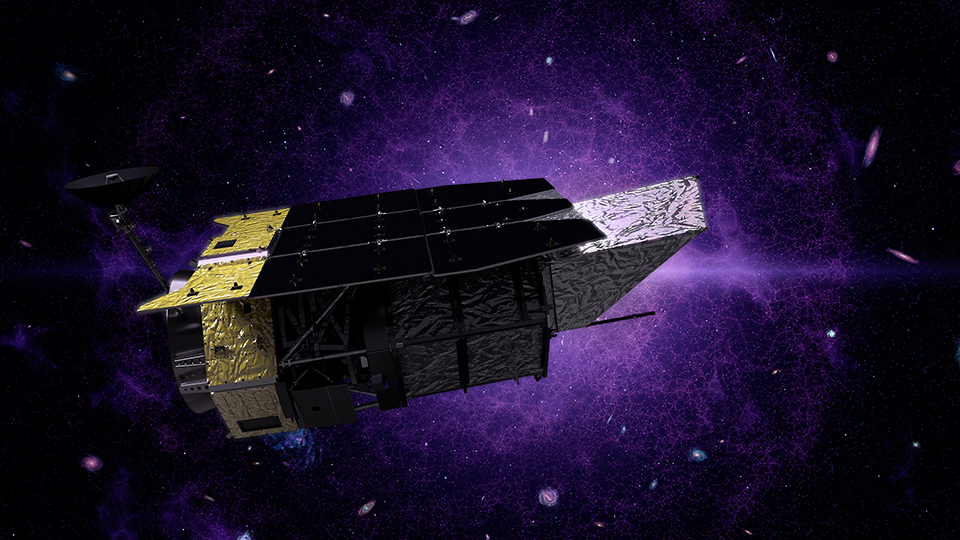

The business the other day launched its TITAN robotic arm, which can carry out in-orbit examinations, repair work, and satellite upgrades.With the rapid development of the satellite industry, Earth’& rsquo; s orbit is progressively crowded with active and inactive spacecraft, noted PIAP.

This busy environment raises the threat of breakdowns, collisions, and lost investments.

Many satellites are still functional in regards to hardware but end up being unusable due to failure in simply one component, the company said.Without robotics, the only way to repair a satellite is to deorbit it and replace it with a completely brand-new one.

This adds to area debris and increasing mission expenses.

That’& rsquo; s why autonomous in-orbit maintenance (IOS) is quickly ending up being a tactical concern for the European Space Agency (ESA) and the worldwide area sector.TITAN is PIAP Space’& rsquo; s action to these difficulties.

The business designed the robotic particularly for on-orbit applications.“& ldquo; TITAN is the most advanced of this type of robotic manipulator ever developed in Poland and most likely among the most capable in its class throughout Europe,” & rdquo; stated Pawe ł Pa ś ko, head of the mechatronics section at PIAP Space.

“& ldquo; We developed it to be scalable, modular, and flexible enough for orbital and planetary missions.

With correct sealing, it can likewise run in dusty environments —-- including the lunar surface covered in regolith.”& rdquo; PIAP is ready for future servicing missionsPIAP developed the high-precision robotic arm for orbital operations such as satellite evaluation, component replacement, docking help, and module setup.

TITAN has a 2 m (6.5 ft.) reach and 7 degrees of freedom, permitting sub-millimeter precision —-- 0.5 mm in positioning and 0.1° & deg; in orientation.The business equipped it with a redundant architecture to make sure uninterrupted performance.

Each joint functions independent power lines, information buses, and thermal control to avoid system-wide failure.TITAN’& rsquo; s modular style also enables the arm to be geared up with numerous customized end effectors, including multipurpose grippers, sensors, and tool user interfaces.

Its universal electrical-mechanical interface enables quick setup for satellite capture, cable handling, refueling, or orbital assembly.

PIAP stated this flexibility makes it ideal for various usage cases —-- from essential maintenance to complicated construction operations in orbit.The Warsaw-based company, functioning as prime professional and consortium leader, revealed the effective conclusion of the engineering design and final testing.

Funded by ESA with a €& euro; 2.6 million ($2.9 million U.S.) agreement, TITAN has attained Technology Readiness Level 6 (TRL 6), proving its functionality in a simulated orbital environment.

This means the system is now all set for combination into future maintenance missions.Register now so you dont miss out on out!TITAN to be adjusted for IOSHEX initiativePIAP is likewise adapting TITAN for the IOSHEX initiative —-- a joint task in between ESA and SAB Aerospace.

The job’& rsquo; s objective is to establish a long-term, in-orbit maintenance platform in low Earth orbit (LEO), where robotic arms like TITAN will perform upkeep and refurbishment tasks.The IOSHEX module will stay in orbit for up to 5 years as a robotic filling station, while the ESA Space Rider automobile will deliver replacement elements and return obsolete devices to Earth for recycling.

PIAP Space is accountable for offering a robotic arm capable of carrying out precise operations in microgravity —-- including on-orbit part replacement and hardware disassembly.PIAP Space has already developed innovative services for planetary expedition, consisting of the robotic arm for the ESA ARGONAUT lunar lander under the MANUS program.

The company has likewise delivered a suite of modular robotic grippers developed under the ORBITA project, contributed to satellite refueling principles, and took part in developing the In-Space Transportation Vehicle (ISTV).

PIAP will officially present the TITAN model on April 14 and 15 throughout the ESA Space Security Conference in Warsaw.The post TITAN robotic arm from PIAP Space aims to automate in-orbit examination appeared initially on The Robot Report.

11

11