Two Glacier systems at work in an MRF in Chicago.

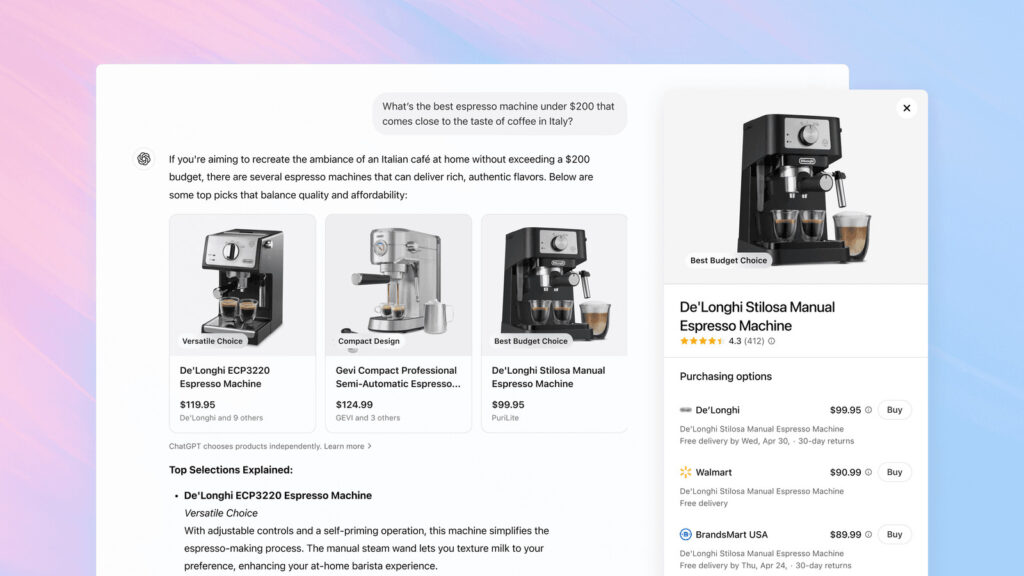

The robots can sort approximately 45 products per minute.|Source: Areeb Malik, co-founder of Glacier, on LinkedInGlacier, which uses artificial intelligence and robotics to effectively arrange recyclable products, today revealed that it has raised $16 million in Series A financing.

The business likewise stated Recology’& rsquo; s King County Material Recovery Facility, or MRF, in Seattle has deployed a fleet of its AI recycling robots.San Francisco-based Glacier said this financial investment caps an advancement duration during which it expanded its existence to markets including San Francisco, Los Angeles, Chicago, Detroit, and Phoenix.“& ldquo; The funding is not only an unbelievable testament to this development trajectory that we’& rsquo; re on, on our quest to allow circular manufacturing; however we’& rsquo; re using the funding in a number of significant methods,” & rdquo; Rebecca Hu-Thrams, co-founder and CEO of Glacier, informed The Robot Report.

“& ldquo; The very first is just to make our hardware, including our robotic and our vision systems, progressively more scalable and quicker to release.”& rdquo; Glacier has actually assembled robots to deal with the unpredictable nature of recycling streams.

Its computer system vision and AI innovation need to recognize and arrange over 30 various types of materials, which can range from typical items such as PET plastic and aluminum cans to particular product packaging types like tooth paste tubes, cat food tins.Glacier constructs out information flywheelHu-Thrams stated that Glacier has significantly been taking a look at its recycling robotics and AI data as 2 parts of the exact same flywheel.

The data makes the robotics much better and more accurate, while the robots gather more data with every pick they make.“& ldquo; What we & rsquo; re truly focused on now is building out that flywheel and likewise comprehending how we can harness that information to solve problems that may even be agnostic of what the robot is right away implied to treat,” & rdquo; Thrams said.

& ldquo; Our supreme vision is for Glacier to become a tool that can be an os for these recycling facilities.”& rdquo; The Ecosystem Integrity Fund (EIF) led the round.

It likewise included involvement from existing investors including New Enterprise Associates (NEA), AlleyCorp, Overture Climate VC, Amazon Climate Pledge Fund, and VSC Ventures.New investors in Glacier included Elysium, Overlap Holdings, Cox Exponential, Alumni Ventures, One Small Planet, and Working Capital Fund.Closing the circular manufacturing loopTo comprehend Glacier’& rsquo; s long-term objectives, you initially need to comprehend how the recycling worth chain works.

It begins with putting recycling bins out on the curb.

Once it’& rsquo; s there, the recyclables are gotten by a truck and required to an MRF, Hu-Thrams said.“& ldquo; The job of that MRF is to generally to take that huge stack of commingled recycling, much of which is likewise garbage, and sort it into constituent commodities as successfully as possible,” & rdquo; she described.

& ldquo; So if the sorting process were best, you would end up with these gorgeous bales of paper, cardboard, plastics, aluminum cans, and so on that these MRFs could offer to end market manufacturers to develop into brand-new stuff.

Now, the sortation procedure, as you can most likely picture, is extremely cumbersome.

It’& rsquo; s extremely pricey, because much of it is still actually done with manual labor.”& rdquo; MRFs experience very high levels of turnover, and if the majority of MRFs can’& rsquo; t find the’labor force, they can & rsquo; t sort the waste into functional materials.

Hu-Thrams said that Glacier is trying to close the loop in circular manufacturing.Ideally, products from recycling bins go to a center, where they are broken down into their specific components, repackaged, and delivered to a manufacturing plant to be made into something else.

Today, however, there’& rsquo; s a damaged link in this circle: the MRFs.“ & ldquo; Think about what these MRFs are doing: They’& rsquo; re taking in feedstock, and after that their task is to produce a particular yield at a particular quality rate, and do all of the quality examination you expect out of a common factory,” & rdquo; Hu-Thrams “said.

& ldquo; And yet, they have numerous less tools than something like a plastic bottling plant.”“& rdquo; & ldquo; They still have a heavy reliance on manual work,” & rdquo; she included.

& ldquo; They still have little by way of data at scale to assist them investigate their procedures and enhance effectiveness.

That’& rsquo; s really the space that Glacier is looking for to fill for them.”& rdquo; Recycling poses sortation challengesGlacier said its robotic expenses half as much as standard choices and requires just 3 ft.

of conveyor space.|Source: GlacierMRFs are handling an exceptionally heterogeneous stream of products that are unclean and really tough to sort.

This has presented numerous obstacles for companies wanting to automate the process.

First, before Glacier, other recycling sortation systems used off-the-shelf robots, which were typically too expensive for the MRF, kept in mind Hu-Thrams.“ & ldquo; Secondly, a great deal of these systems were simply physically large and really space-consuming in an environment that is very space-constrained,” & rdquo; she included.

& ldquo; Imagine a robot that takes up the space of three to 4 sorters on a sort line and gets the job done of one.”& rdquo; Finally, MRFs, like making plants, live or pass away based upon their upstream,” & rdquo; Hu-Thrams “said.

& ldquo; This means they need very trustworthy systems that can stay running in spite of the extremely variable material stream.“& ldquo; They & rsquo; re not simply processing bottles and cans and paper, however also seeing things like Christmas lights and surf boards and microwaves and car motors and even things like guns and hand grenades,” & rdquo; she said.

& ldquo; How do you create a system that is versatile enough to work effectively with that type of material stream? This is why we chose that purpose-built was the way to go.”& rdquo; Glacier uses off-the-shelf elements from reputable OEMs, Hu-Thrams stated.

The company sourced these parts independently to assemble a robot that is compact, has a high uptime, and a faster return on financial investment (ROI).

In truth, Hu-Thrams said a variety of Glacier’& rsquo; s customers have actually gotten their ROI in less than a year.

For recycling, a three-year turn-around would be considered quick, she said.Register now so you dont miss out on out!Glacier helps MRFs get the most from the information it gathersThroughout our conversation, Hu-Thrams emphasized Glacier’& rsquo; s commitment to putting its customers’ & rsquo; requirements initially.

This is true when it pertains to costs, uptime, payment models, clients’ & rsquo; rights to service their robots, and, possibly most notably, AI.“& ldquo; We will go to our recycling facility customers and ask, what are the products, or the kinds of things, that you care the most about?” & rdquo; Hu-Thrams “said.

& ldquo; We & rsquo; ve actually utilized that method to expand the manner in which we’& rsquo; re building our AI taxonomy.”& rdquo; For example, Glacier works to find ways for its clients to use their information to improve the general performance of the plant.

“& ldquo; As we & rsquo; ve grown out our database and as we’& rsquo; ve grown out the abilities of AI, we’& rsquo; re actually seeing a great deal of clients using the data as a standalone product, like a common factory,” & rdquo; Hu-Thrams said.

& ldquo; We & rsquo; ve actually helped many customers recognize and measure up to a million dollars in incremental revenue they’& rsquo; re currently sending to the garbage dump every year, and after that we can assist them fine-tune their strategy and see real-time where those modifications made any impact to their overall recovery rate,” & rdquo; she continued.Looking forward, Hu-Thrams said that she hopes Glacier won’& rsquo; t just be a robotics or an AI data company, however also a partner to assist recycling centers solve top-line problems.

For example, if a customer was having issues with contamination in its paper stream, then Glacier could install vision systems and robots in tactical places to help enhance its purity rate.“ & ldquo; We now, possibly for the very first time, can truly assist these centers comprehend in genuine time, at the product level, what’& rsquo; s entering, what & rsquo; s coming out in their bales, and what’& rsquo; s being ejected to the land fill,” & rdquo; said Hu-Thrams.

“& ldquo; We give them this healing tool to in fact make sure that they’& rsquo; re choosing in a specific way.”& rdquo; The post Glacier generates $16M and announces brand-new Recology King implementation appeared initially on The Robot Report.

12

12