INSUBCONTINENT EXCLUSIVE:

the first rocket field by renewable, clean-burning fuel a reality.The second stage that Orbex will use employs bio-propane for its fuel,

which will reduce carbon emissions by as much as 90 percent vs

the kerosene based fuel used on most similar vehicles

partner SLM to make this possible

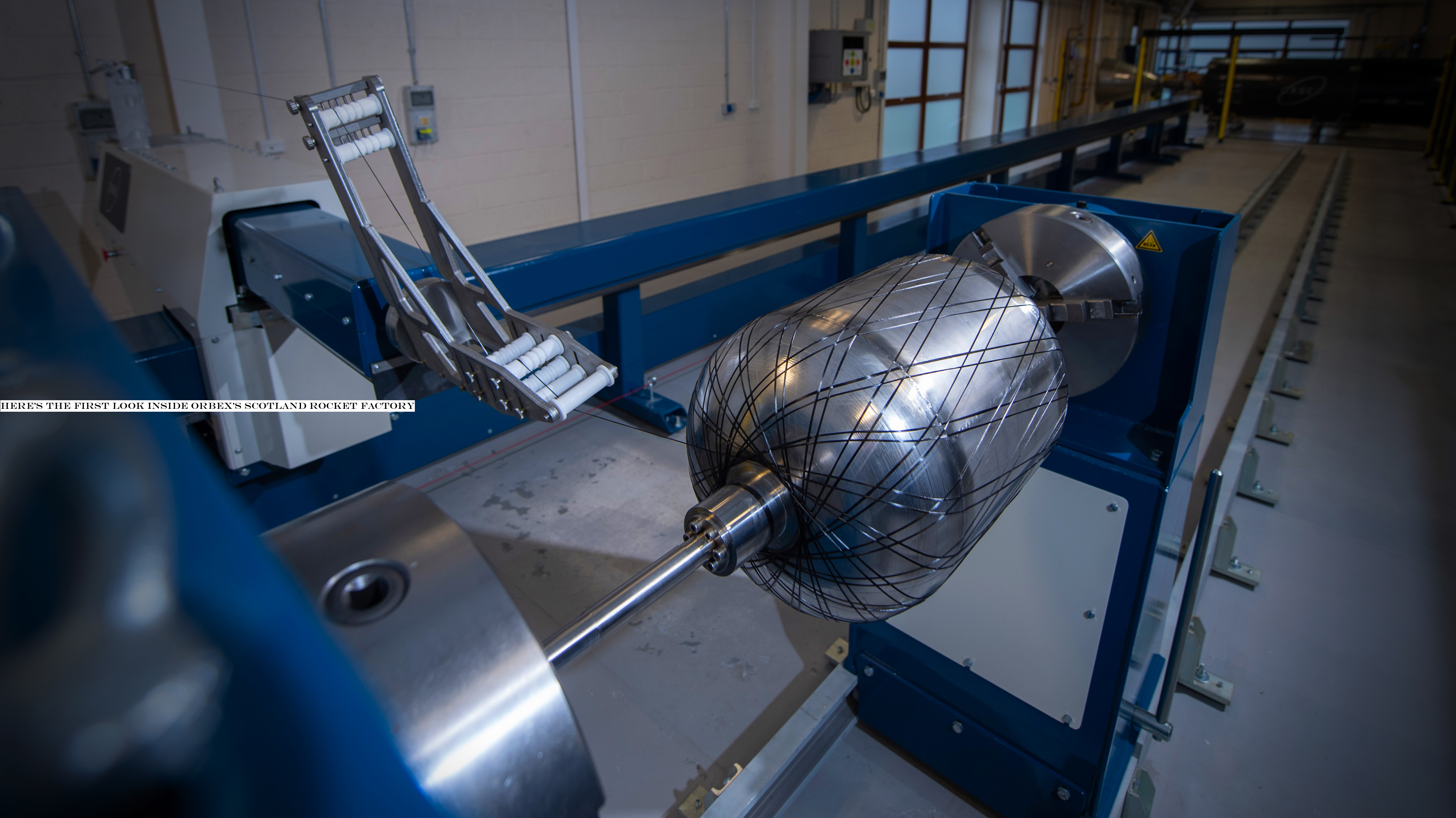

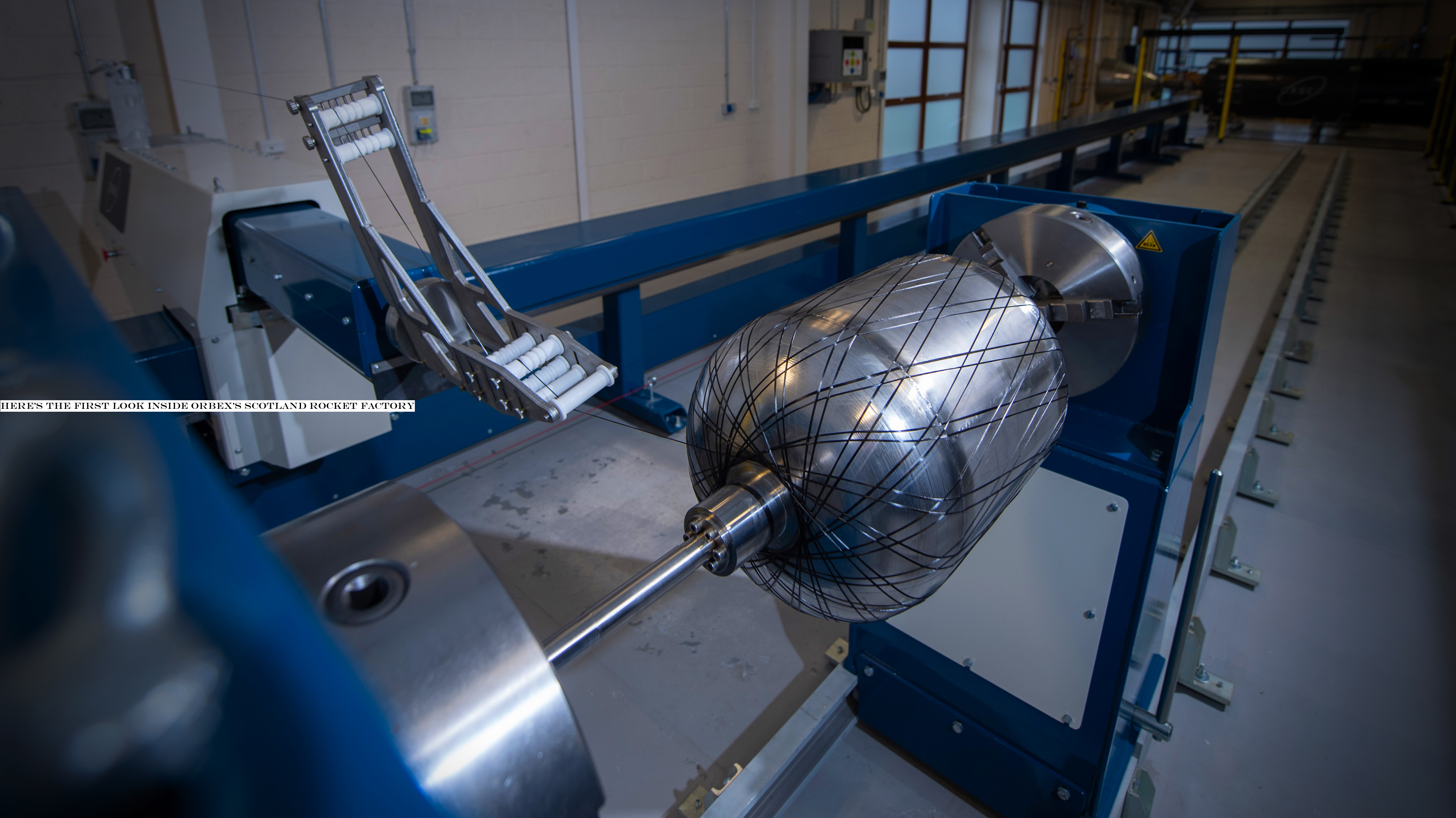

That will add more structural reliability to the engine, the company says.Orbex carbon fibre winding machine.In service of making this

feet long and which can produce its rockets with a weight savings of up to 30 percent vs

similarly sized vehicles already on the market

That weight savings means faster acceleration and more fuel efficiency.Also part of the new facility is a large autoclave that is used to

bring the rocket components to the proper temperature for setting and curing

The company says that its equipment can wind its main stage fuel tanks in just a matter of hours using this equipment, which is a big part

of ability to achieve launch vehicle construction efficiency, which leads to affordable costs for small satellite launch clients keen to

seventh, vacuum-rated one to power the second stage as it makes the final trip to orbit to delivery its payloads.Orbex already has a number

of commercial contracts in place, and expects to fly Prime for the first time sometime in 2021

orbital spaceport once complete.